In modern architecture and construction, safety plays the most pivotal role. Gradually, with an increase in awareness, regulations regarding installation have brought fire-rated glass to the limelight, making it a crucial element in commercial, residential, and industrial buildings. But, definitely not all suppliers provide an equal measure of reliability, quality, and compliance. Picking a reliable fire rated glass manufacturer enables you to have your building projects kept at fire safety standards without compromising on their aesthetics or performance.

In this blog, we shall cover the top qualities of a reliable fire rated glass manufacturer, in an attempt to help architects, contractors, and developers make well-informed decisions to better design for safety.

1. Time-Honored Experience and Industry Knowledge

A time-honored experience in manufacturing fire rated glass takes the topmost priority in terms of qualities that a dependable manufacturer must possess. Fire rated glass is a very specialized product that must stand hard and fast tests for thermal resistance, structural integrity, and safety from fire under extreme conditions. Those manufacturers who have a time-honored experience have a comprehensive understanding of the complexities involved and offer products that meet or exceed requirements established by the standards all too well.

Look for manufacturers who have:

- A number of years in the fire safety glass market

- A broad portfolio of successfully completed projects

- Expertise in serving both standard and custom applications

Such manufacturers generally have good, streamlined systems to handle the whole gamut of testing, certification, and documentation in order to keep you on the right side of the law and free from any hiccups during the entire process.

2. Certified Fire Safety and Product Testing

The second trait of a fire rated glass manufacturer is product certification. Reliable manufacturers conform to a particular number of specifications and national or international fire safety standards such as:

- UL (Underwriters Laboratories)

- BS EN (British Standard European Norm)

- ASTM (American Society for Testing and Materials)

- IS (Indian Standards)

A trustworthy fire rated glass manufacturer subjects its products to stringent fire resistance testing, comprising insulation, integrity, and radiation control. Fire testing certificates must indicate ratings of usually 30 to 120 minutes, with valid test reports issued by certified labs.

In addition, architects and contractors should be provided with clear documentation that bears fire test certificates, performance data sheets, and installation instructions.

3. Technological Innovation and Manufacturing Capabilities Fire Rated Glass Manufacturer

In this competitive environment, a fire rated glass company must not remain stagnant. Their product catalogues should include everything from fire-resistive glazing to laminated and tempered solutions to answer different structural requirements.

Leading manufacturers should be investing in:

- High-temperature bonding technologies

- Multi-layer glass compositions

- Low iron glass options for maximum transparency

- Acoustic and UV-resistant features along with fire safety

They should also build and be able to produce custom shapes, sizes, and edge finishes—not compromising performance for modern design.

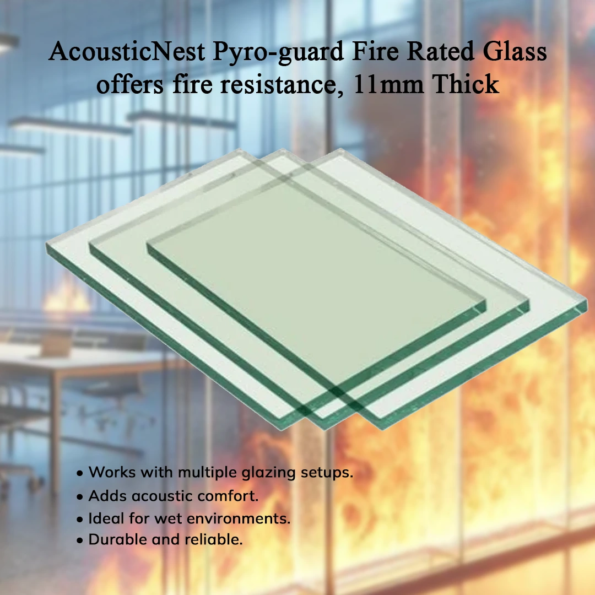

Acoustic Nest is one of the very familiar names in the industry and garners accolades for merging the best technical capability with excellent safety compliances with deliverance of certified fire rated glass manufacturer solutions around the world for both the aesthetic and utilitarian considerations.

4. End-to-End Compliance Support and Documentation

In construction, compliance is a huge issue. A reliable fire rated glass manufacturer will provide complete support, starting at specification and design consultation and culminating in final certification.

Elias has:

- Installation instructions

- Fire rating labels

- Third-party testing certificates

- Technical support during audits and approvals

The technical team is fully versed with local building codes and global standards, thus making sure that your project goes through the inspections smoothly. Such reliable documents assist in building confidence in the manufacturer as well as in saving time during the approval stage of a project.

5. Quality Assurance and Timely Delivery

Plaguing large projects are matters of compromises on quality and tardy deliveries. An assured manufacturer of fire-rated glass will rise above these on account of in-house strict quality control mechanisms and an equally strong production planning.

Indications of consistent practices would be found in the:

- High-grade raw materials

- In-house QA/QC at every stage in production, including the final acceptance checks

- Batch traceability and warranty

- Automated systems handling large-volume orders

The manufacturer will also be able to maintain timely deliveries by keeping adequate inventory, working in close coordination with logistics and transport departments, and maintaining scalable production lines-a very important consideration in a construction that goes by the calendar.

6. Customer Support and Long-Term Partnership Approach

It goes without saying that the relationship between the fire rated glass manufacturers and their clients goes beyond a mere exchange of goods or furtherance of business interests. The reputed manufacturers develop long term partnerships where their experts provide continuous support throughout the lifecycle of the product, starting with selection and installation and all along post-sale.

Place your trust in their support for:

- Site visits and technical assessments

- Training of contractors and installers

- Follow-up services and warranty replacements

- Queries and issue resolution in record time.

Having a reliable partner means that the partner is taking the initiative, promptly reacting, and demonstrating interest in your completion rather than just seeking to score sales. This will avoid delays, improve coordination, and increase client satisfaction.

Conclusion

Choosing the right manufacturer for fire rated glass is not just the price you pay; it is also the quality, safety, and peace of mind you gain. Whether it is your hospital, commercial tower, data center, or residential high-rise, your fire-rated glazing must meet the highest standards of performance and compliance.

To sum up, the top traits of a reliable fire rated glass manufacturer include but are not limited to:

- Proven experience and market reputation

- Certified products through rigorous testing

- Advanced manufacturing capabilities

- Full compliance support and documentation

- Consistently high quality and reliable supply chain

- Strong customer support and long-term servicing

A partnership with a party such as Acoustic Nest would guarantee tested, certified, and high-performance fire rated glass solutions uniquely tailored to meet your architectural vision and safety requirements.

🔥 Key Highlights: Characteristics Before Deciding on a Fire Rated Glass Manufacturer

The safety of the building and the installation being bent to code and design flexibility are entirely dependent on having a good fire rated glass manufacturer. Here are some qualities that set a good company from the others within the fire safety glass industry:

✅ 1. Documented Experience

A worthy fire-rated glass manufacturer undergoes years of practical on-the-ground experience levering into a portfolio of completed projects such as commercial buildings, hospitals, airports, and industrial facilities.

✅ 2. Certified Fire Protection Standards

They supply glass that is tested and certified under global standards, such as UL, BS EN, ASTM, AND IS. Thus, all products carry valid fire rating documentation (ranging from 30 minutes to 120 minutes) and third-party lab validation for safety compliance.

✅ 3. Modernized Manufacturing and Innovation

Leading manufacturers make use of cutting-edge technology in producing laminated, toughened, and multi-layered fire-rated glass. These extra features include sound insulation, UV protection, and low iron content for optical clarity.

✅ 4. Full Compliance Support

Full technical support is offered by a reputable fire rated glass manufacturer right from the point of design selection through to installation advice, plus all compliance documents that smoothen the approval process for architects and builders.

✅ 5. Quality Assurance at All Stages and Quick Shipping

A company would not fail to institute quality control measures at every stage of production and with a fine logistics network in place to bear the brunt of urgent deliveries- even against orders for large quantities or customization.

✅ 6. Commitment Extended to Clients

The likes of Acoustic Nest provide long-term after-sales support and transparent communication with a partnership-based approach that will give long-term value to your project.

Here are 5 FAQs

1. What is fire rated glass and why is it important for modern building construction?

Fire rated glass is glazing specially engineered to sustain high temperatures for a defined duration (typically 30,60,90, or 120 minutes). It impedes flame, smoke, and heat transit, hence affording sufficient time to occupants to safely evacuate. So, disrupted by un-certified triple-glazing manufacturers, it becomes hard to ensure glass complies with legal safety standards and provides life-saving fire protection to buildings like hospitals, offices, schools, and all kinds of residential towers.

2. How can I be sure how good a manufacturer of fire rated glass is?

A dependable fire rated glass manufacturer must have a relevant certification (UL, BS EN, ASTM etc.), an experienced team, strong portfolio, and transparent documentation of compliance. It should provide test certificates of its products and furnish installation manuals and full support to the customer. Their products should be tested and conform to international fire-resistance standards; moreover, they should offer an end-to-end service, including design advisory and after-sales support.

3. Can they also be used for aesthetic or design-oriented projects?

Yes, fire rated glass nowadays is produced to combine the objectives of fire safety and aesthetics. These come in several variants, such as clear or low iron, laminated, or with decorative finishes. Acoustic Nest is a manufacturer specialized in achieving high-performance fire rated glass which can blend with modern architectural elements without compromising on fire safety regulations.

4. What kind of fire ratings must I look for in fire rated glass products?

Fire ratings usually range between 30 and 120 minutes. What rating is applicable depends on the given application and local building code. Most trusted fire rated glass manufacturers will set out recommended product options for consideration based on the specification of your project whether it is for partitions, doors, curtain walls, or windows so as to fulfill both performance and regulatory requirements.

5. What about after-sales service – is this an important consideration when choosing a fire rated glass manufacturer?

Yes, it is. Dependable fire rated glass manufacturers will continue offering technical support long after the sales process, including installation training and warranty assistance, thereby guaranteeing proper installation and long-term reliability. Companies like Acoustic Nest hold their customers’ interest to heart with this ongoing customer support as well as a partnership-focused service attitude towards clients, all of which are necessary for great projects on a large scale and excellence in sensitive projects.

Shop

Shop Acoustic Foam

Acoustic Foam Acoustic Curtain

Acoustic Curtain Ceiling Acoustics

Ceiling Acoustics E-POD

E-POD Wall Acoustics

Wall Acoustics Floor Acoustic

Floor Acoustic Acoustic Homez™

Acoustic Homez™